Against the backdrop of the rapid development of the modern textile industry, theJofeng Dyeing & WeavingWe know that manufacturing equipment and technology is the key to enhance the competitiveness of our products. We always adhere to the concept of "promoting high efficiency with intelligence, building quality with technology", continuously investing in advanced equipment and intelligent systems, and building a digital, informationized, automated and integratedIntelligent Quality SystemThe

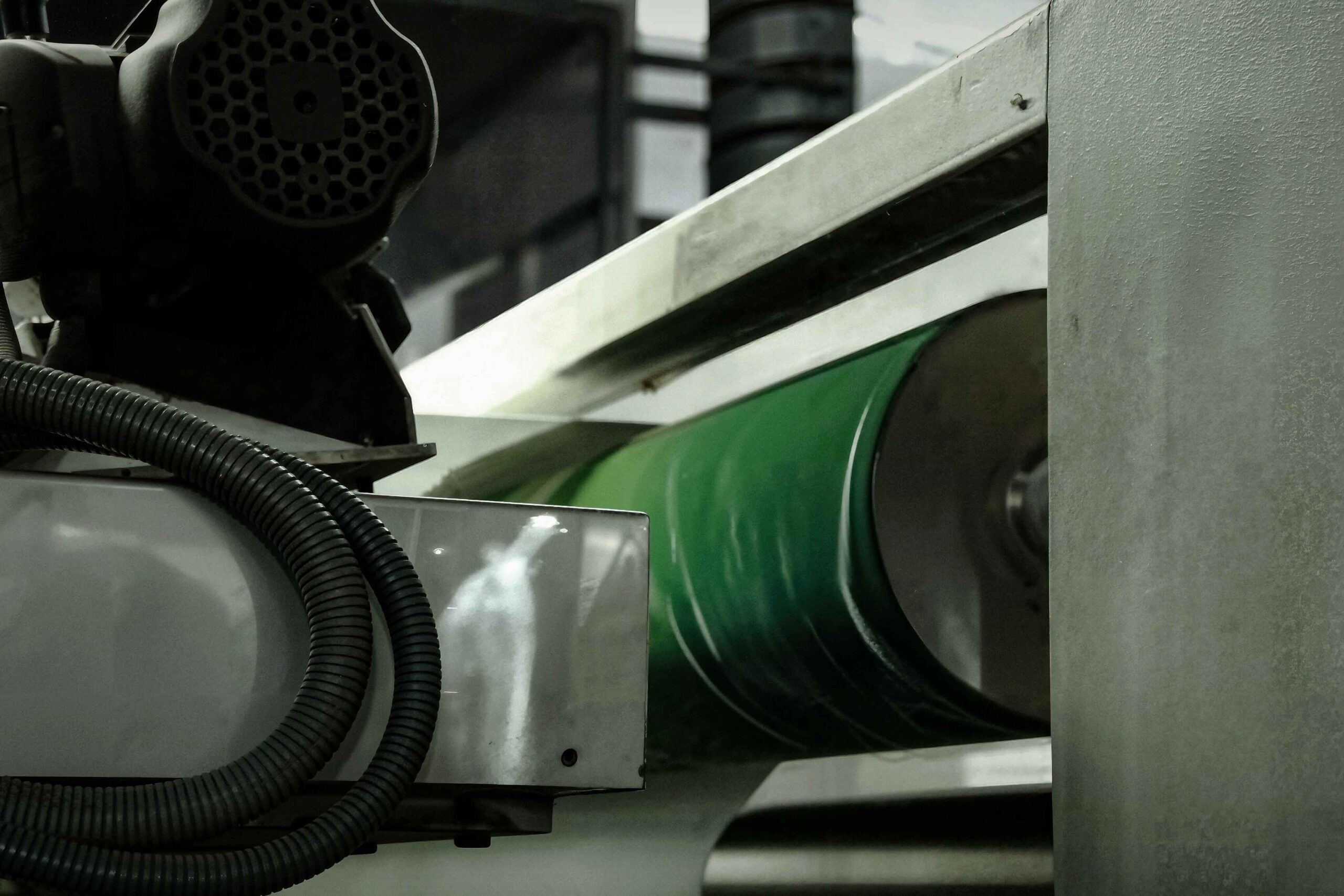

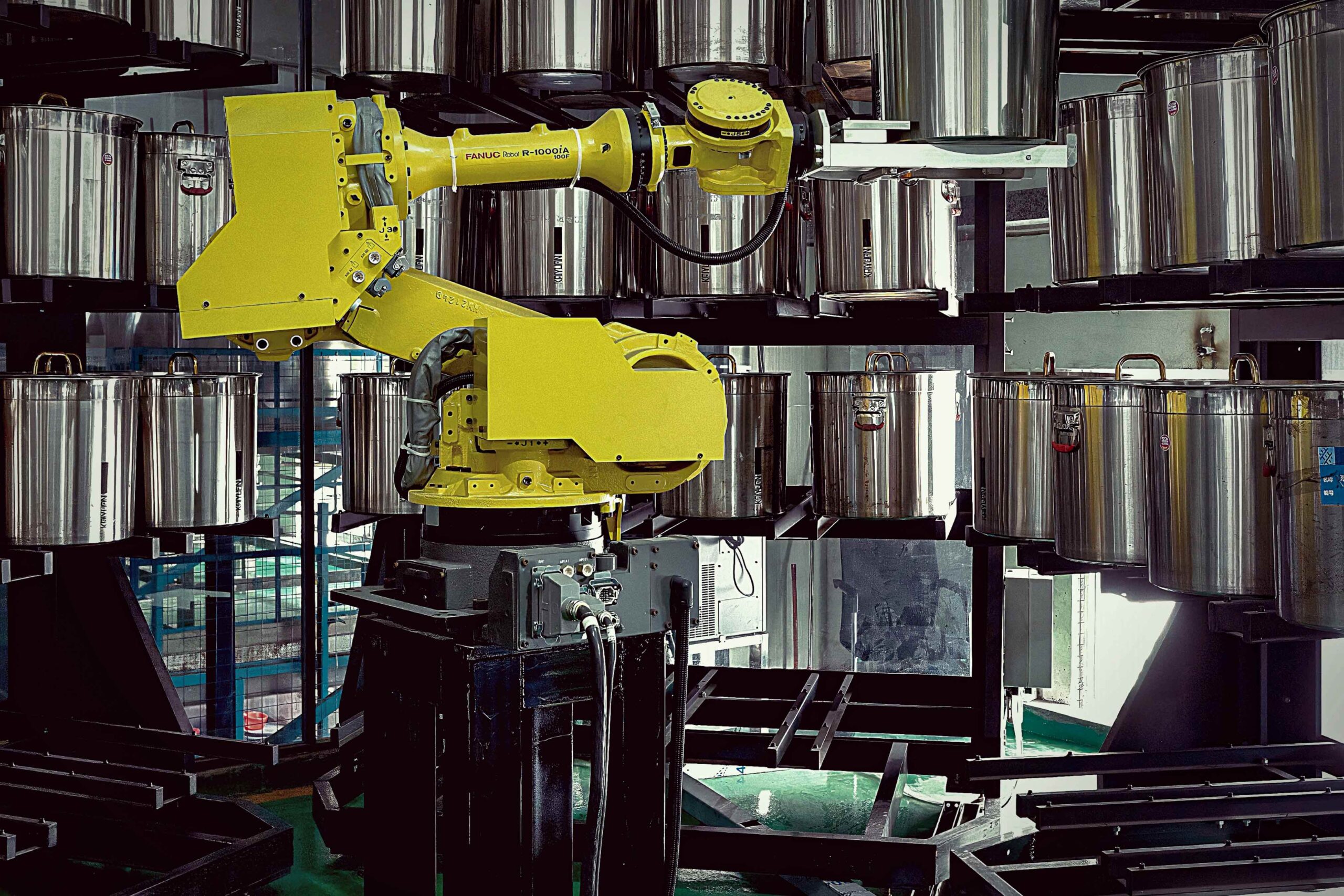

Our production bases are fully equipped with advanced textile and dyeing and finishing equipment from Germany, Italy, Japan and other countries, includingAutomatic Sizing Machine, Intelligent Fabric Inspection System, High Precision Continuous Dyeing Line, Automatic Stretching and Setting Machine, Energy Saving and Environmentally Friendly Heat Recovery Systemetc. These equipments not only significantly improve the production efficiency, but also ensure the key qualities of fabrics such as uniform color, stable size and excellent handfeel.

In textile smart manufacturing, we buildMES Manufacturing Execution SystemIt realizes the digitalized control of the whole process from raw material warehousing, production scheduling, process execution, quality inspection to finished product warehousing. At the same time, the application of intelligent sensing device and data collection module enables us to grasp the real-time operation status of the equipment and process implementation, early warning of potential failures, and improve the equipment crop rate and safe production level.

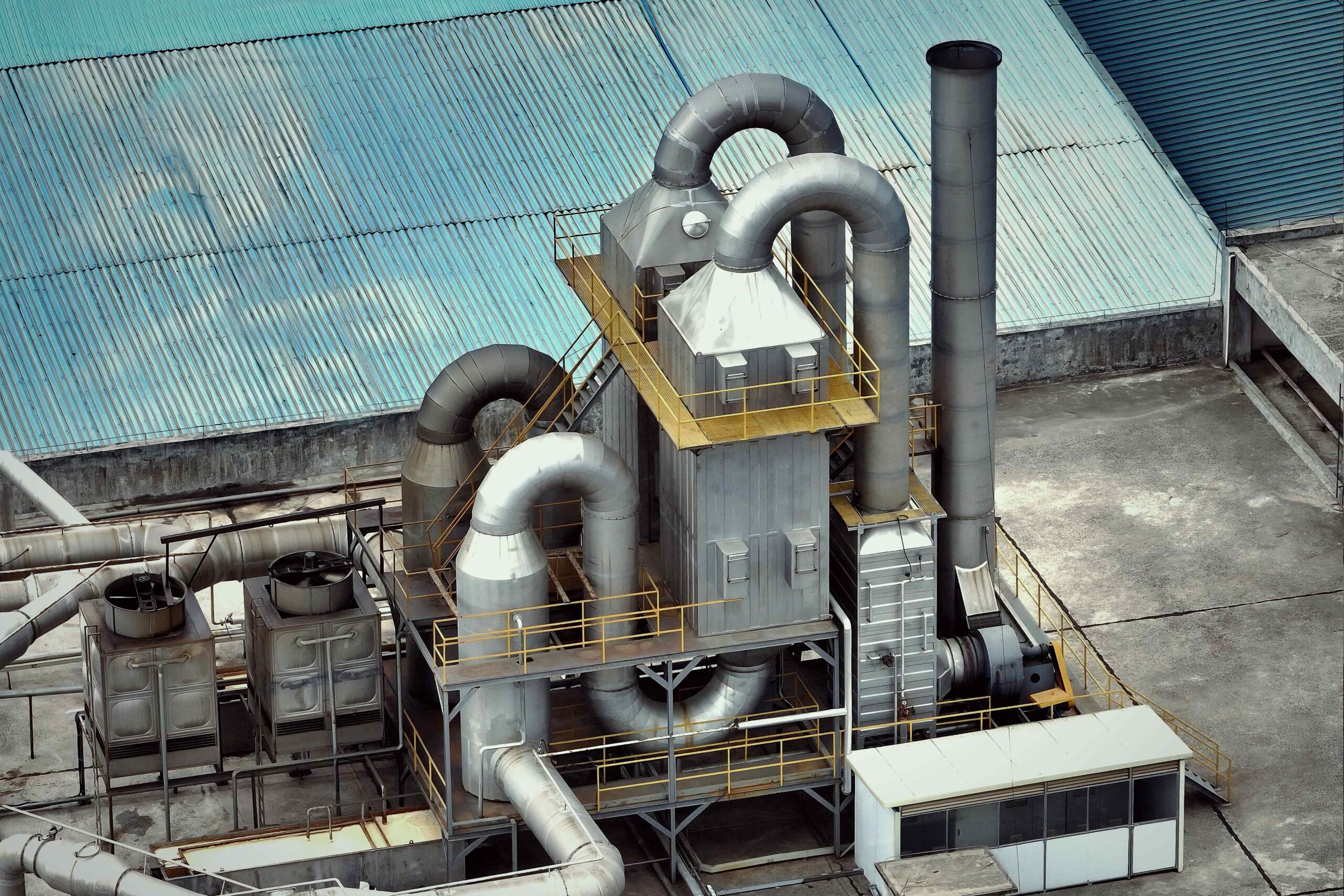

In the dyeing and finishing process, we adopt environmentally friendly and energy-saving dyeing tanks and intelligent liquor dispensing systems, which significantly reduce energy consumption and emissions by precisely controlling the temperature, liquor ratio, and the proportion of dyeing and chemical materials, and comply with global environmental standards. At the same time, the accompanying automatic water quality monitoring and wastewater treatment system ensures that every drop of discharged water meets the standard, demonstrating our responsibility for sustainable development.

Intelligent quality manufacturing is not only a technological innovation, but also a commitment to quality and the realization of customer trust. Through the dual drive of hardware upgrading and system optimization, we provide our global customers with more stable, more efficient and greener fabric solutions, and help brands achieve more outstanding product power.